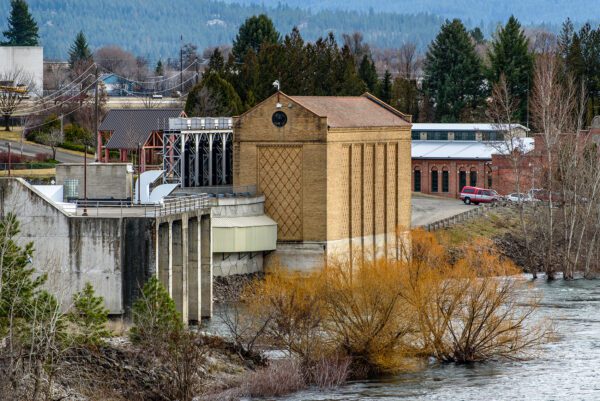

As part of its carbon-reduction plan, Washington State Ferries (WSF) is converting its ferries to run on electricity rather than fossil fuels. This conversion creates significant work for welders and maintenance staff at WSF’s Eagle Harbor Maintenance Facility. WSF has added shifts to keep up with demand, and its maintenance facility is now operating 24 hours/day. The facility, however, was not designed for 24-hour operation, with welding taking place outdoors or in a small shop building, which is not ideal for nighttime work.

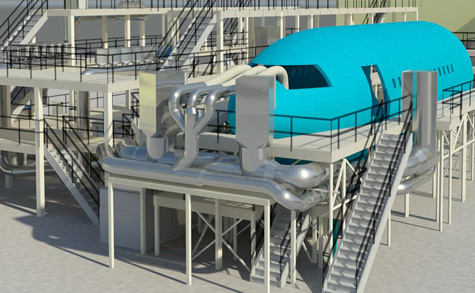

To support welders and maintenance staff, WSF is upgrading the Eagle Harbor campus with a new weld shop building and renovations to the machine shop and storage areas. TKDA is leading the project, and FSi is the mechanical, fire protection, and electrical engineer. As part of the design process, FSi worked with the welders to make sure that the final design meets their needs.

To help WSF meet its sustainability goals and the 2021 Washington State Energy Code, the project includes sustainable features such as solar readiness and an efficient heat pump system. All-electric building systems increase electricity demand. FSi designed the new building systems to avoid an electrical service upgrade, balancing the project’s need for sustainability and electric building systems with the limited electrical capacity available to the site.